Seed Grants

The Consortium for Innovation in Manufacturing and Materials (CIMM) solicits proposals for CIMM Seed Funding each year to support research projects relevant to CIMM’s advanced manufacturing themes. The current Science and Technology Thrusts (STTs) of CIMM address underlying technologies in two areas:

1) STT1 (Multiscale metal forming and replication) addresses challenges in high-throughput manufacturing of components with functional features ranging from microns to millimeters and beyond with high fidelity and repeatability;

2) STT2 (Laser-based 3D metal printing) focuses on adaptive manufacturing of application-specific structures with a high degree of geometric and microstructural complexity and variability.

The unifying scientific challenge for these STTs is the multiscale nature of the underlying phenomena, which span multiple length scales (nanometers to millimeters and beyond) and time scales (nanoseconds to hours).

A major challenge in multiscale forming is that well-established macroscale manufacturing methods cannot be simply scaled down to the relevant dimensions. To address this, STT1 tightly couples experimentation with modelling and simulation on multiscale plasticity and physics and mechanics of interfacial regions, with focus on mechanical size effects and engineered interfaces.

A major challenge in laser-based 3D metal printing is that an understanding of the complex interplay between multi-physics and multiscale phenomena—which are required for tailoring composition and microstructure of printed parts—is presently incomplete. To address this, STT2 couples experimentation with hierarchical modeling and simulation tools, with a focus on laser printing processes and custom powder synthesis.

Experimentally validated models and simulation tools, developed through this effort, will lead to advancement of scientific understanding and acceleration of further technology development. CIMM’s research program also includes the development of data handling and workflow management capabilities to support material and process development within the Integrated Computational Materials Engineering (ICME) framework. CIMM is developing multiple facilities in the State to support advanced manufacturing research and development, and also coordinating a network of user facilities on multiple campuses where CIMM-affiliated users are given access at the same rates charged to the on-campus users. Collectively, these are called CIMM Core User Facilities (CIMM-CUF).

Seed Grants in Year 1

- Ch

ris Arges, LSU: Manufacturing of multi-scale metal structures with vertically large aspect ratios through bottom-up block copolymer self-assembly coupled with conventional top down lithography.

- Prabhu Arumugam, LA Tech: Evaluation of 3D-Printed Titanium Micropillars – Toward a Novel Electrochemical Nanoprobe Technology for Multi-Analyte Brain Sensing

- Fengyan Lu, LSU: Positron Annihilation Lifetime Spectroscopy Defect Analysis for Laser-based 3D Metal Printing

- Erica Murray, LA Tech: 3D Printing of Pt-Au Electrodes for NOx Sensing

- Ying Wang, LSU: Carbon Nanotube Reinforced Metals by Laser-based Additive Manufacturing with Desirable Mechanical Properties

Seed Grants in Year 2

Hamzeh Bardaweel, LA Tech: 3D printable structures for multi-functional vibration energy Scavenger

- Kasra Momeni, LA Tech: An advanced phase-field approach to engineering laser-based 3D metal printing: effect of mechanics and interfaces

- Kidong Park, LSU: Dynamic analysis of 3D printed metal parts with non-contact laser interferometry

- Jonathan Raush, ULL: Measurement and Characterization of Thermophysical and Thermochemical Properties of Liquid Metal Alloys for Laser-Based 3D Metal Printing Modelling and Optimization

- Shuai Shao, LSU: Development of Atomistically-informed Interface Dislocation Dynamics Simulator

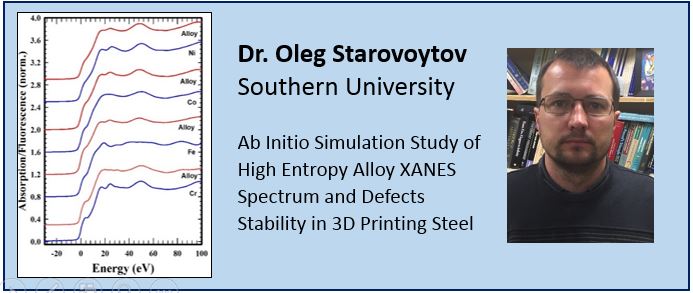

- Oleg Starovoytov, SUBR: Ab Initio Simulation Study of High Entropy Alloy XANES Spectrum and Defects Stability in 3D Printing Steel

- Shaomian Yao, LSU: Selective Laser Melting 3D printing to fabricate titanium medical implants favoring osseointegration