“We Just Call It Work”

Farmers across Louisiana rely on LSU AgCenter’s cutting-edge research and technological advances in what’s now called precision agriculture—using remote sensing, machine learning, and big data on farms—to get bigger yields and larger profits while protecting the environment for future generations. But some just call it work.

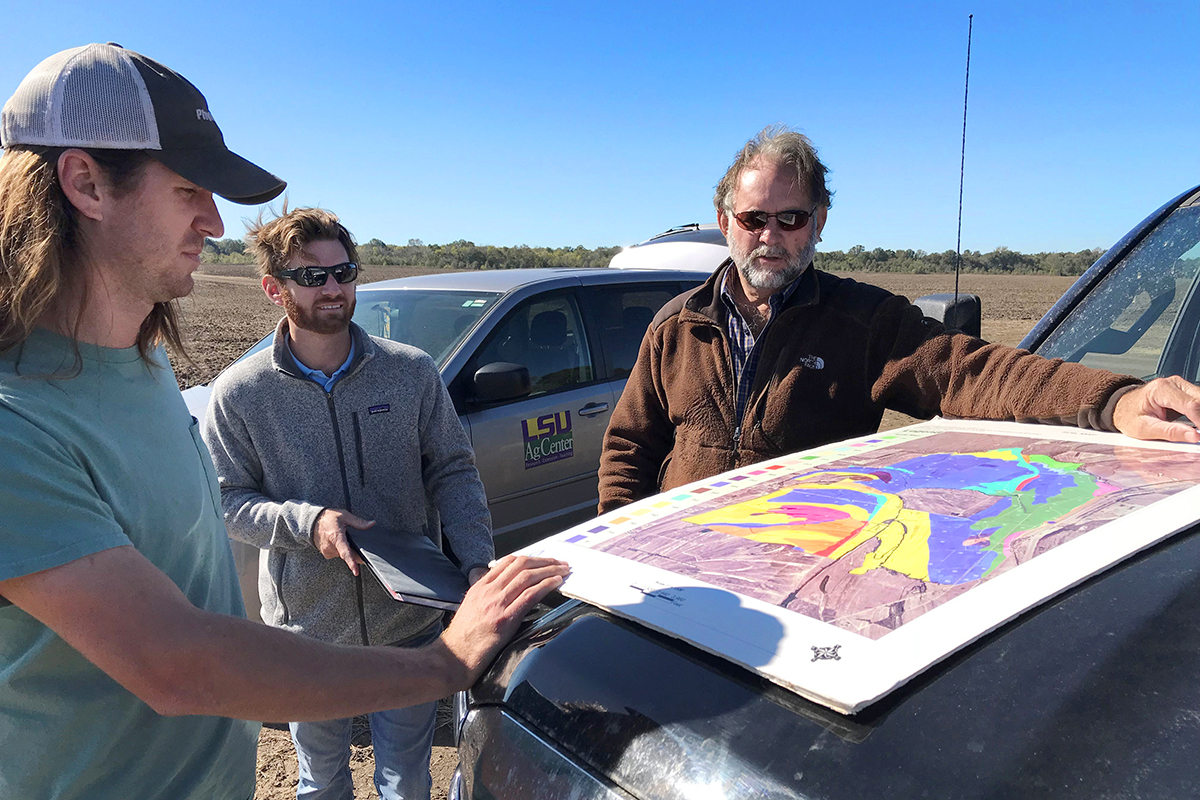

Marshall, Mead, and Jay Hardwick farm on 8,000 acres in Tensas Parish. By collaborating

with LSU and the AgCenter and benefiting from recent research and development in precision

agriculture, including satellite imaging and data analysis, the family has been able

to save money on inputs (seed, fertilizer), get bigger yields, and minimize their

impact on the surrounding ecosystem.

Kyle Peveto

Mead Hardwick is a fourth-generation farmer in Tensas Parish in the northeastern part

of the state, a couple of miles from the Mississippi River, along Highway 65. He farms

with his brother Marshall and his dad, Jay Hardwick. When invited to a Zoom meeting,

he joins via video link from his tractor. Why not? The tractor practically drives

itself and although Hardwick does have to turn it around when he reaches the end of

the field, he’s surrounded by technology to help him and his family optimize every

bit of energy and money they spend across Hardwick Planting Company’s 8,000 acres

on a portion of Somerset Plantation’s 20,000 acres. The tractor has real-time kinematic

(RTK) auto-steer and doesn’t swerve more than an inch to the left or right; there’s

a GPS receiver on the roof; and right behind, there’s a variable-rate fertilizer applicator

that’s pre-programmed to release specific amounts only in certain areas according

to a “prescription map” loaded into the tractor’s on-board computer. On a colorful

screen by the steering wheel, Hardwick can watch himself like an avatar advancing

through the harvested soybean field where the colors on the map show differences in

nutrient levels.

Modern farm machinery not only harvests crops but also lots and lots of data. As Hardwick

chats about various projects on Zoom, his tractor and other machines can record information

about the soil and the crop and link it automatically to longitudes and latitudes.

He doesn’t have to walk or drive up and down each row with a clipboard to take notes

like “Need more fertilizer on this area about two-thirds of the way down.” The tractor

knows exactly where it is and what is needed.

“We’ve had a long relationship with LSU and the AgCenter,” Hardwick said. “LSU has

helped us find the sweet spot with our variable rate fertility program and how to

have truly sustainable agriculture. Working with LSU has also helped me be confident;

they’ve answered questions and given us access to tools we otherwise would not have.

When we want to test something, it’s ‘Here’s an idea,’ and ‘Let’s go do this.’ Having

this relationship with LSU on gathering and analyzing data and really understanding

the numbers has been seamless.”

“We work hard to make the knowledge tangible; we have to. Otherwise, when we go to a farmer, he’ll say, ‘I can’t apply that, I can’t spend the money,’ and the farmer will then decide to do something else. Just like people talk about evidence-based medicine, we try to do evidence-based agronomy—using actionable data that’s customized for each grower, we can provide what-if scenarios and show exactly how much profit is possible by doing one thing as opposed to another.”—Luciano Shiratsuchi

Hardwick wasn’t destined to become a farmer, nor was his father, Jay Hardwick, who

was a college arts professor in photography until he and his wife Mary decided to

move back to Louisiana to join her family farm in 1981.

“My dad didn’t know a corn plant from a cotton plant when he started,” Mead Hardwick

said. “So, he had to latch onto something that quickly could get him up to speed.

Luckily, he had LSU and the AgCenter Northeast Research Station, which is only about

13 miles from our farm.”

Mead Hardwick himself worked in the finance world and real estate development in Dallas,

Texas until 2014.

“I should maybe say this off the record, but I actually had an overlap for about a

year between farming and real estate because I honestly wasn’t sure if this farming

thing was going to pan out,” he said.

But it did, and he now looks forward to his own children becoming the fifth generation

of the Hardwick Planting Company, which also encompasses forest as a natural wildlife

refuge for the Louisiana black bear. On their 8,000 acres of tillable farmland, the

family grows soybeans, lots of corn and cotton, and smaller amounts of winter wheat

and grain sorghum.

When it comes to his and his dad’s relative inexperience with farming in the beginning,

Mead Hardwick considers it an asset.

Drone footage of test plots in a rice field. By using artificial intelligence and

training a computer system to recognize the edges of fields and planted areas and

then analyzing those areas for plant vigor, Thanos Gentimis, assistant professor in

the LSU AgCenter Department of Experimental Statistics, helps farmers capture information

not yet visible to the human eye—pinpointing spots that might need more seed or fertilizer.

Photo courtesy of Thanos Gentimis

“What has allowed us to move into some really advanced things and experiment based

on the latest in technology and research with LSU is that we got to break the cycle

of ‘Dad did it this way’ or ‘Dad did it that way’ and really take a different approach,”

he said. “The younger farming generation like myself sometimes struggle to convince

the older generation to move forward, so we’re fortunate. The kind of experimentation

we’ve done can’t go on if you’re fighting an intragenerational technology battle.

That’s how we got to doing precision agriculture and getting the equipment that has

enabled us to embrace it fully.”

While Jay Hardwick had no prior experience in agriculture, he quickly got up to speed.

He’s now one of the most well-known farmers in the state and was just inducted into

the Louisiana Agriculture Hall of Distinction, which recognizes those who have made

significant contributions to Louisiana’s farming, ranching, forestry, aquaculture,

education, and agribusiness industries. He was recognized for having made cotton farming

more environmentally friendly by focusing on production techniques that have minimal

impact on the surrounding ecosystem. Jay Hardwick has previously received the National

Cotton Achievement Award, the National Award for Environmental Sustainability, and

the U.S. Environmental Protection Agency’s Environmental Excellence Award. He also

serves as chairman of the American Cotton Producers of the National Cotton Council.

The Hardwicks work in close collaboration with Precision Ag Coordinator Luciano Shiratsuchi,

associate professor in the LSU School of Plant, Environmental & Soil Sciences, and

Thanos Gentimis, assistant professor in the LSU AgCenter Department of Experimental

Statistics. While Shiratsuchi is an agronomist, Gentimis is not—he’s a mathematician

who also happens to be quite good at chess. LSU AgCenter hired both of them to help

launch the university’s digital agriculture program in 2018 and interest among students

has skyrocketed. Gentimis came from health informatics and now is applying the same

expertise (machine learning, artificial intelligence) to improving agriculture, so

it’s not lost on him nor his students that the toolboxes they’re building could be

valuable in many contexts. A recent graduate got a job as a data analyst to help improve

the safety of Louisiana buildings.

By using machine learning and artificial intelligence, Gentimis is developing software that can learn from outcomes on one farm or with one particular crop or variety to make predictions for others. It’s all about pattern recognition.

Using vast datasets, Gentimis trained a computer system to recognize the edges of

fields and areas with different amounts of vegetation based on drone and satellite

images (remote sensing). Next, each defined area is analyzed for plant vigor—the normalized

difference vegetation index, or NDVI, can measure plant health and capture information

not yet visible to the human eye—pinpointing spots that might need more seed or fertilizer

and getting that information to the farmer in real time. The biggest advantage Hardwick

sees in this approach is its incredible speed, in two ways. First, he can buy a satellite

image of their vast farm, use it to generate a prescription map, and have the tractor

out rolling in the field the next morning, applying what’s necessary. Second, the

research findings from Shiratsuchi and Gentimis are already at scale—there’s no need

to translate or extrapolate from research results in a lab or on a small test patch

to the 8,000-acre farm.

“Anytime somebody comes up with an idea in a lab or a small plot, you say, ‘Those

are very positive results, but can that be replicated on a large scale?’,” Hardwick

said. “That’s not to say research isn’t always useful—it gives you an idea of what’s

possible. But it often has a ways to go before you can translate it on the farm and

it becomes economically viable. Also, what we’re trying to figure out is what we can

do today—not tomorrow, but today. With the tools I have in my toolbox, what will that

let me do today?”

Here, he speaks the same language as Shiratsuchi.

“We work hard to make the knowledge tangible; we have to,” Shiratsuchi said. “Otherwise,

when we go to a farmer, he’ll say, ‘I can’t apply that, I can’t spend the money,’

and the farmer will then decide to do something else. Just like people talk about

evidence-based medicine, we try to do evidence-based agronomy—using actionable data

that’s customized for each grower, we can provide what-if scenarios and show exactly

how much profit is possible by doing one thing as opposed to another.”

Drone photo of LSU students studying precision agriculture with Luciano Shiratsuchi

and Thanos Gentimis. The students come from various disciplines—animal sciences, renewable

natural resources, mathematics, experimental statistics, computer science, entomology,

as well as plant, environmental, and soil sciences. From left to right (front row)

Felippe Hoffman, Silva Karp, Prakash Dangal, Korey Nuchia, Hugh Bullard, Sumanth Vissamsetty),

Benjammin Meritt; (back row) Daniel Forestieri, Murilo Martins, Thanos Gentimis, Kelly

Arceneaux, Lovepreet Singh, and Alexander Tryforos.

Photo courtesy of Thanos Gentimis

The amount of data processing necessary, however, cannot be done on a regular computer.

Gone are the days of “let me check the books” or transferring years of farm data on

a flash drive.

“The massive tangle of raw data that comes from precision agriculture is like a fertile

field full of potential but, just like in farming, if the right tools and seeds are

not used, the field will never produce much,” Gentimis said. ”We believe the right

tools can be found in data analytics and machine learning, since the datasets involved

have long surpassed the abilities of traditional models for analysis and prediction.”

To meet the research program’s needs for high-performance computing, Gentimis combines

local servers with resources in the cloud. He and Shiratsuchi also collaborate closely

with industry. Ag-Analytics, a farm management platform led by former Cornell University

associate professor Josh Woodard has quickly developed a global reach in helping farmers

improve efficiency by melding automated sensor data from farm equipment with satellite

imaging and machine learning. When the Ag-Analytics team launched their university

partnerships, they came to LSU first.

“We went to where the top researchers were, and it’s become a great partnership,”

Woodard said. “Farmers on our platform have an option to confidentially share aggregated

datasets with researchers at their land-grant university. Our system translates and

calibrates the data so we can layer it all onto one cohesive geospatial grid to make

predictions in real time to help farmers and support the land-grant extension system.”

The crops Shiratsuchi and Gentimis have focused on optimizing so far are sugarcane,

soybeans, rice, corn, cotton, sweet potatoes, wheat, and sorghum—industries with an

estimated total annual economic impact of about $6.4 billion.

“Short of launching hybrids that don’t need fertilizer, precision agriculture is the

only way for farmers to save money and the environment, using fewer resources while

getting the same or better yield,” Shiratsuchi said. It’s the only practical way to

improve efficiency and reduce contamination, using only what you need and where you

need it.”

Mead Hardwick agrees.

“We grow commodity crops for which there is a set market price,” he said. “We can’t

do much about the price, so to increase our profitability, we need to control our

cost, produce more, and be more efficient. Being strategic with our nutrients, especially,

has been key for us. It feels good, too, considering how nutrient runoff contributes

to the ‘dead zone’ in the Gulf of Mexico.”

When the Mississippi River meets the Gulf of Mexico, it brings agricultural runoff

from about a third of the country with it, as far north as Minnesota. When fertilizer,

such as nitrogen and phosphorus, hits the Gulf, it’s a feast for algae, which multiply.

But as the algae die and decompose, they consume the oxygen in the water, causing

“dead zones” void of aquatic life. This low-oxygen condition is known as hypoxia,

and the Hardwicks and the LSU AgCenter are currently involved in a four-year research

project funded by the Patrick F. Taylor Foundation to help solve this problem.

“Overall, in America, we’re still applying much more nitrogen than we need,” Shiratsuchi

said. “But you don’t gain anything from applying the same blanket amount across the

board; instead, you lose. You can’t treat the farm as a uniform field and use averages

for everything.”

By using machine learning and artificial intelligence, Gentimis is developing software

that can learn from outcomes on one farm or with one particular crop or variety to

make predictions for others. It’s all about pattern recognition. And while we’re still

far from “self-driving farms,” the benefit of data-driven “smart farms” is becoming

clearer each day—especially as rapidly changing environments make it harder and harder

to rely on experience.

Even when something goes terribly wrong, precision agriculture technology can help.

When Hurricane Laura wreaked havoc in southwestern Louisiana this August, farmers

and insurance agents were able to assess and document the damage faster using remote

sensing, so insurance payments could go out.

Advanced data analytics will increasingly become part of any “normal” day on the farm,

researchers and farmers predict.

“I love tech, but I don’t think of it as ‘tech’ or ‘precision agriculture,’” Hardwick

said. “We just call it work.”

Elsa Hahne

LSU Office of Research & Economic Development

ehahne@lsu.edu